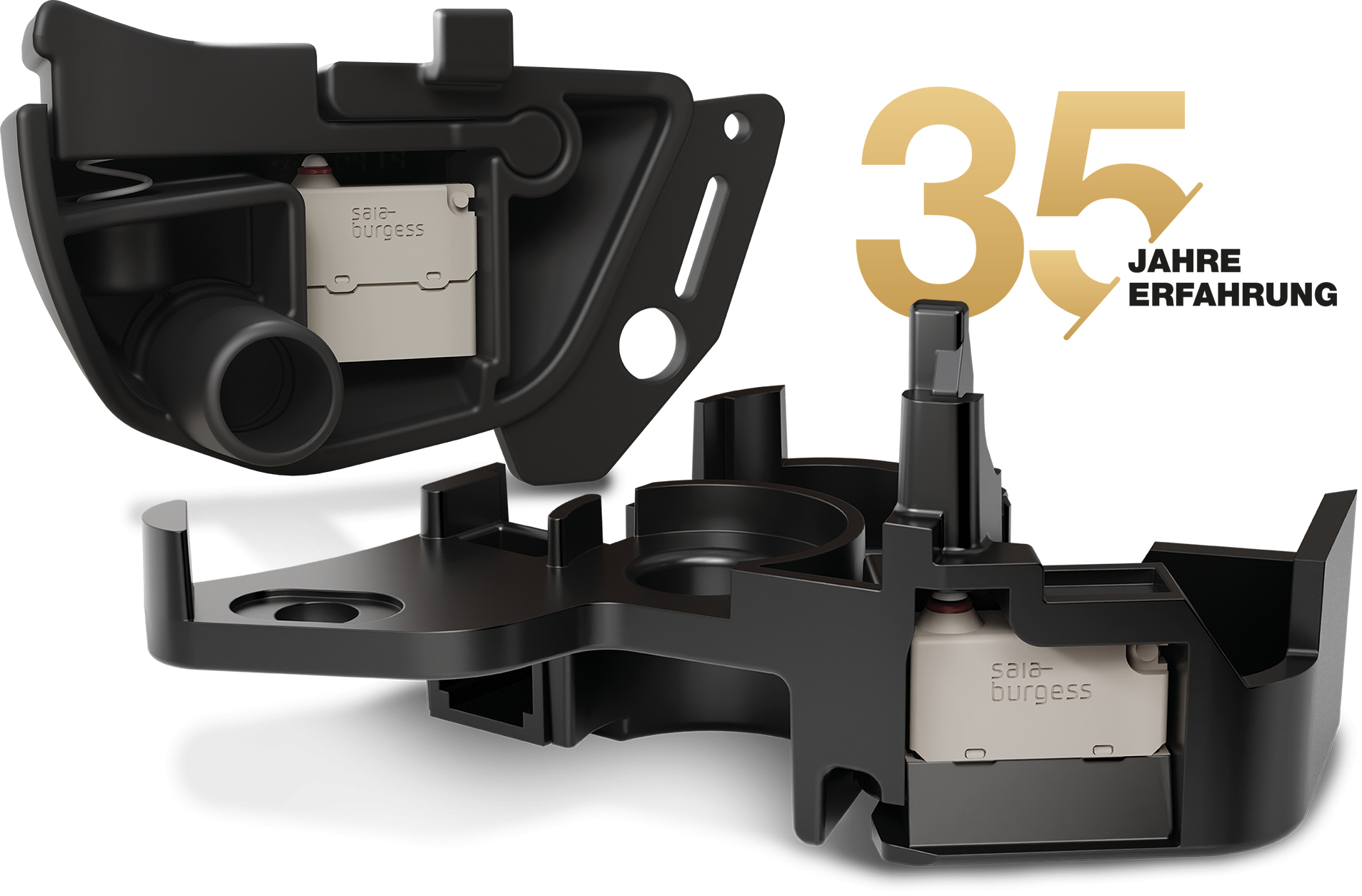

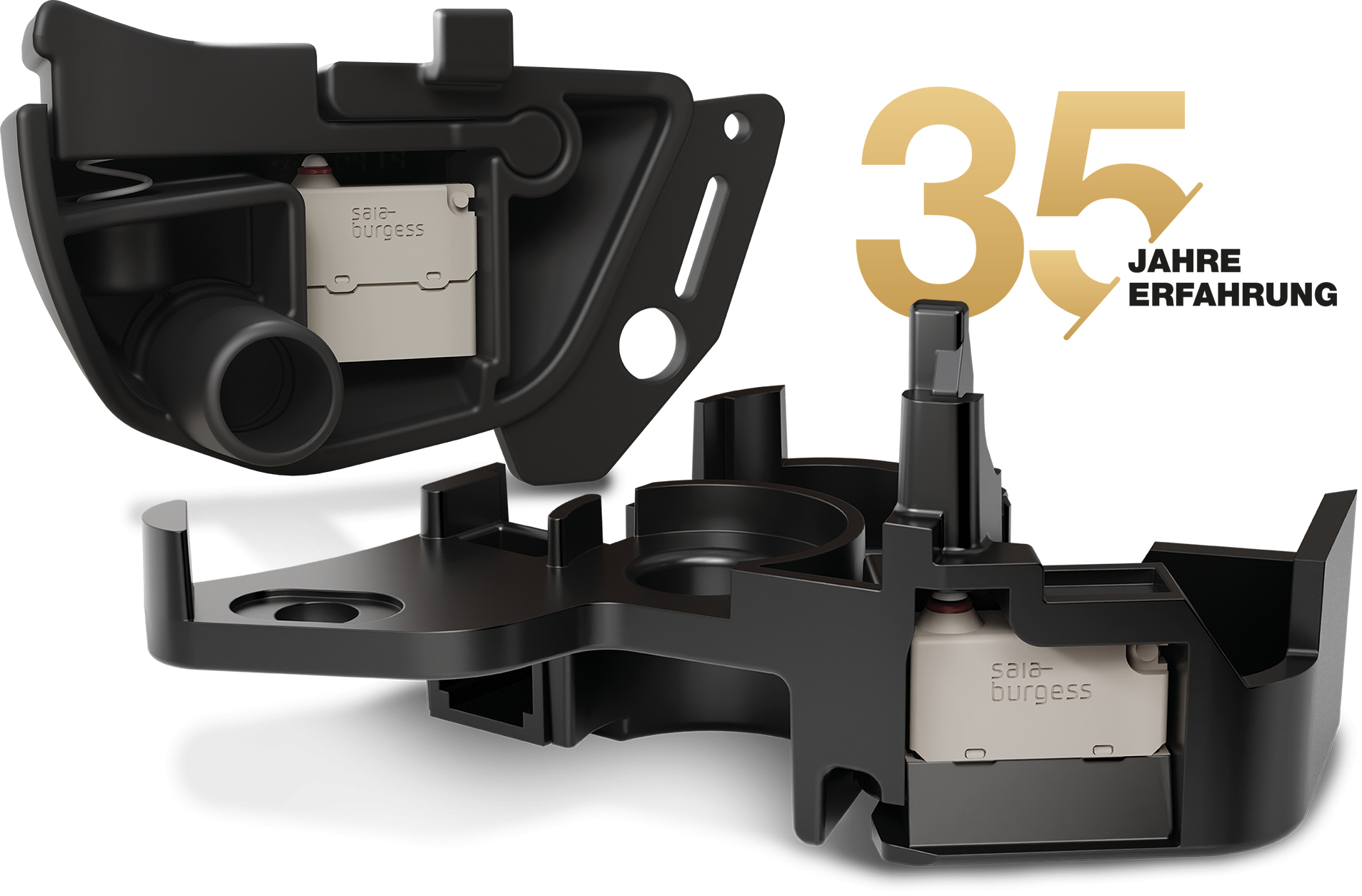

From concept to series production

-

Development and design (2D/3D)

-

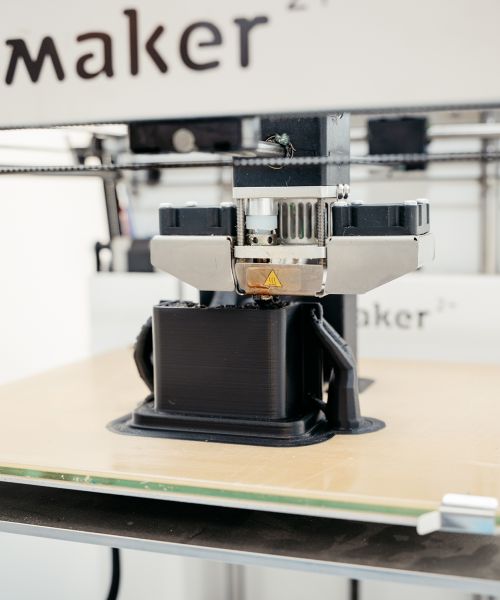

Prototyping & in-house laboratory testing

-

Series production in flexible quantities

-

100% final inspection & traceability

Development, Testing and Production

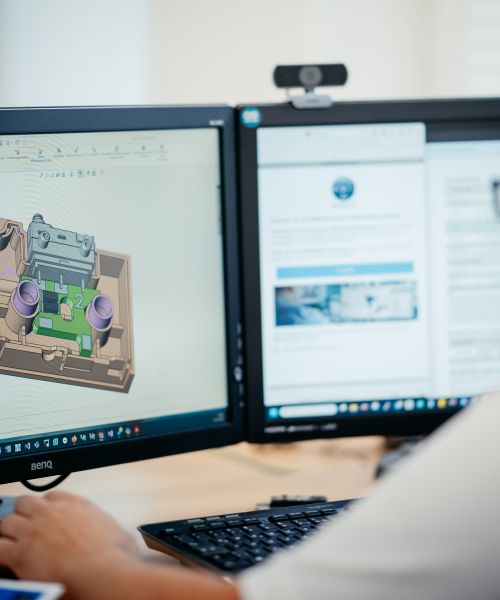

Development

-

Custom planning & design

-

Creation of 2D and 3D drawings

-

Prototype production with 3D printing

-

Development of tools for series production

-

Custom planning & design

Testing

-

Lifetime and stress tests

-

Temperature and climate change tests

-

Electrical and mechanical function analyses

Production

-

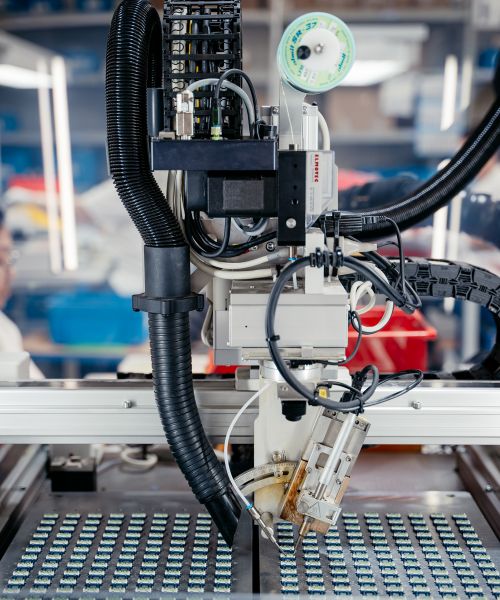

Assembly, crimping, soldering, potting, injection molding

-

100% final inspection with documented results

-

Traceability of every component

-

Flexible production capacities

Technology & Equipment

Planning

Prototyping

Testing

Automation

Our services

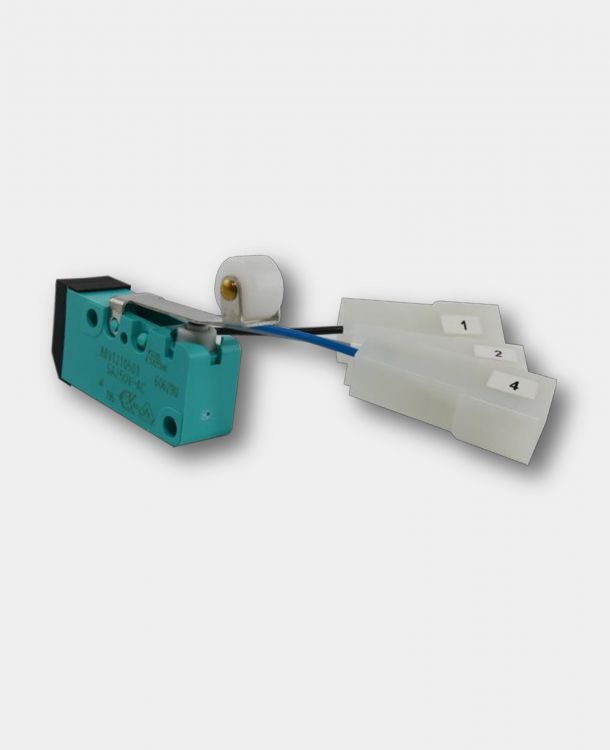

Adapt your microswitch to your application.

Design

Actuators

Connections

Design

Actuators

Connections

Specifications

Custom solutions

Diagnostics

Specifications

Custom solutions

Diagnostics

Examples

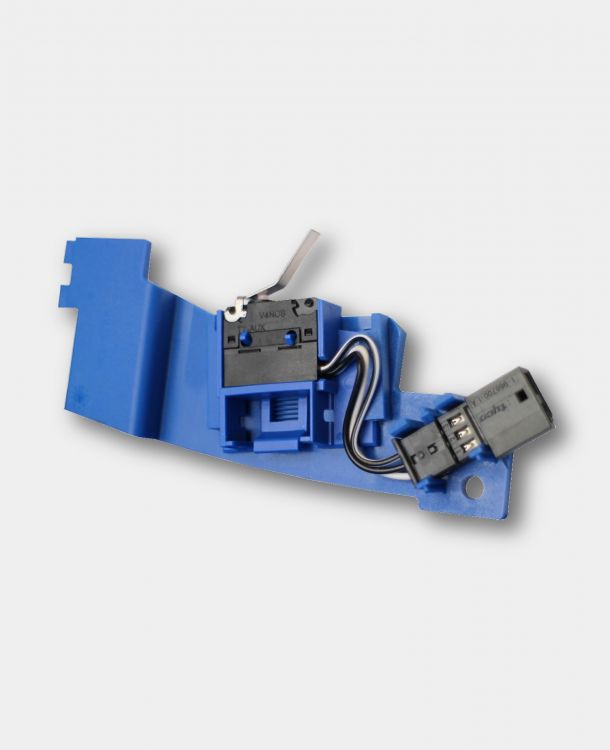

Industrial trucks release switch

Diagnostic switch

Bus swivel seat detection

Passenger car easy entry

Passenger car clamp detection

Rail vehicle door detection

Truck gearshift knob position

Wind turbine motor brush monitoring

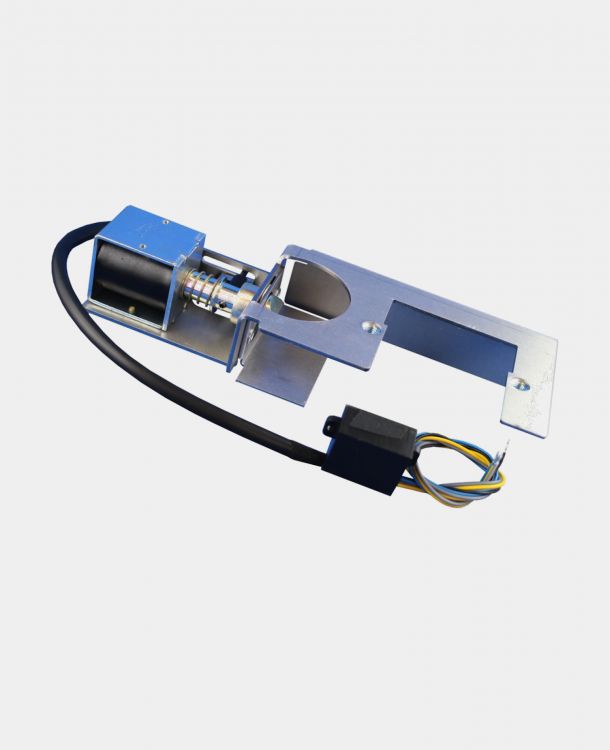

Safety locking system

Safety locking system

Questions and Answers

Development of customer-specific applications

Clever solutions – simple, elegant, precise! Microswitches present special challenges for the development environment.

Exact dimensions require precise planning and the highest level of care in implementation. We design, engineer, and realize your requirements in the shortest possible time.

We provide for you:

- Product specifications

- All necessary 2D/3D drawings

- Components for small series using the laser sintering process

- Rapid prototypes produced with 3D printing

- Design and production of tools as well as assembly and production aids

- Definition of test equipment according to your requirements

- Implementation of test specifications for series production

- Production of pilot series up to full-scale production

- Complete documentation from order to series delivery

Your application and our technical know-how – the perfect connection.

Our Equipment:

- Modern CAD systems for processing and creating all common 3D formats

- Design and development of customer-specific electronic components

- Test laboratory for validation of electrical and mechanical customer requirements

- 3D printers for producing prototypes and test samples

- Climate chamber for temperature and climate cycle tests

- Test systems for customer-specific solutions incl. archiving of test results for traceability

- Modern automatic potting system

Our Services:

- Standards research

- Feasibility analyses

- Prototypes

- Lifetime tests

- Electrical and mechanical analyses

- Microscopic examinations

- X-ray diagnostics

- Microsection analyses

- Initial sample inspection reports

- IMDS entries

Production with Quality

Customer satisfaction is our top priority. We guarantee the highest quality under economic conditions. Thanks to our long-standing expertise in production, we manufacture products at the highest level. Our services include assembly, soldering, potting, and 100% end-of-line testing.

Innovations – individually developed, powerfully produced

We deliver flawless products to ensure maximum customer satisfaction. Controlled processes in our production guarantee consistently high quality. With modern manufacturing methods, we realize the combination of various components and accessories, the modification of existing standard components, and the production of complete system solutions. This is complemented by customer-oriented project management, a fully equipped tool shop, and an integrated injection molding facility.

Our customers set the benchmark for our quality and are at the center of all our efforts. The foundation is the consistent compliance with legal and customer-specific requirements in distribution, development, and production. Our ultimate goal: maximum customer satisfaction.

Key aspects of our quality management:

- Quality control from incoming goods through production to delivery – no product leaves our company without passing the final inspection

- Zero-defect policy within the framework of Total Quality Management

- Personal responsibility of every employee for the quality and environmental performance of their work

- Sustainability in all areas of activity and continuous improvement of processes and services

- Collaboration exclusively with partners who meet our high quality standards

The quality management system of switch-it GmbH is certified according to DIN ISO 9001:2015.

A microswitch is a mechanically operated electrical switch. DIN 41635 and DIN 41636 refer to snap-action switches and distinguish between design types A to E (installation dimensions, connection types, switching principle).

Below is an overview of the terms used in DIN 41636.

Forces- Operating start force: Force required to move the actuator from its rest position.

- Operating force: Force needed at the actuator to move it across the switching point.

- Overtravel force: Force necessary to hold the actuator in its end position.

- Release force: Force to which the operating force must be reduced so that the snap mechanism returns to its initial position.

- Differential force: Difference between the operating force and the release force.

(Diagram of forces and travel of a microswitch)

Actuator positions

Actuator positions

- Rest position: Position of the actuator when no external force is applied.

- Operating point (mechanical): Point on the actuator’s travel where the snap mechanism is activated.

- End position: Position of the actuator at the end of its permissible travel.

- Release point (mechanical): Point on the actuator’s return travel where the snap mechanism resets to its original position.

- Pretravel: Distance between rest position and operating point.

- Overtravel: Distance between operating point and end position (at least 50% must be used to ensure reliable switching).

- Release travel: Distance between end position and release point.

- Free travel: Distance between release point and rest position.

- Total travel: Sum of pretravel and overtravel, or release travel and free travel.

- Differential travel: Distance between operating point and release point.

(Diagram explaining rest position, operating point, end position, and release point)

Our customer-specific solutions are applied in numerous industries – from automotive and industrial trucks to commercial vehicles, as well as renewable energy and drive and control technology.

How do we develop microswitch solutions?Microswitches pose special challenges for the development environment. Exact dimensions require precise planning and the highest level of accuracy in implementation. We design, engineer, and realize your requirements in the shortest possible time.

How do we ensure quality in production?We manufacture flawless products to ensure high customer satisfaction. Controlled processes in our production guarantee the highest quality under economic conditions.

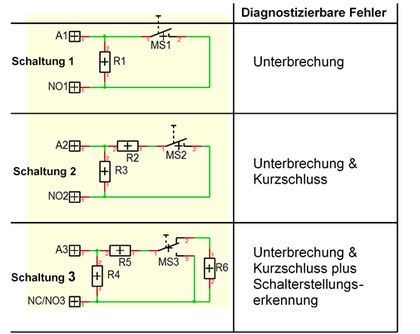

With increasing safety requirements in the automotive sector, in industrial trucks, commercial vehicles, and mechanical engineering, the demands on microswitches and their installation environment have also risen. Defective connectors, short circuits, and interruptions in connection lines must be detected by the onboard electronics. Diagnostic capability is achieved by integrating resistors into the microswitches.

The resistors are potted together with the connection leads, ensuring the switches remain IP67-compliant. No additional installation space is required for the added diagnostic capability and the basic dimensions of the microswitch remain unchanged.

Circuit types- Circuit 1 and 2: In combination with a control unit, switch positions, short circuits, and interruptions can be evaluated via voltage levels.

- Circuit 3: In addition to short circuit and interruption detection, resistor coding enables the evaluation of a changeover switch using only two leads.

Sizing

The resistor configuration causes power dissipation, which in turn leads to an increase in switch temperature. This affects the operating temperature range and must be considered during application design.

switch-it diagnostic microswitchesswitch-it offers various diagnostic microswitches for applications in control circuits. The products are based on switches from Johnson Electric, which have been in worldwide use for decades and have proven their reliability billions of times.

Do you have questions about one of our products? We are always available to help you.